Zinc Flake Coatings

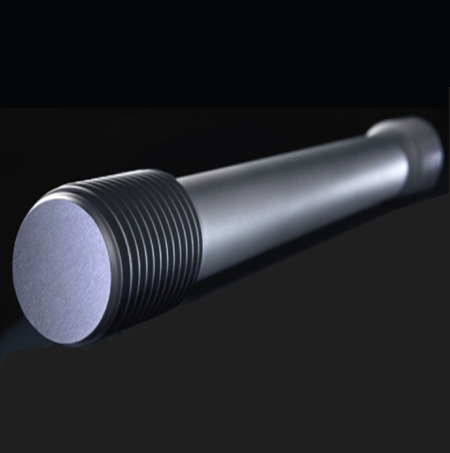

We are Manufacturer, Supplier, Exporter, Services Provider of Eco Friendly Zn Al (Zinc Aluminium) Flake Coatings, Corrosion Resistant, Abrasion Resistant, UV (Ultra Violet) Resistant, Chemical Resistant, Non Stick Surface Protection Coating for High Tensile Fasteners, Threaded Connecting Hardware Parts, Sintered parts, Bolts, Nuts, Rivers, Screws, Spring Steel Parts, Clips Clamps, Brackets, Stamping Parts, Brake Disc, Brake Drum, Brake Rotors and Our setup situated at Pune, Maharashtra, India.

Zinc - Aluminium Flake Coating Technology

New generation Eco-Friendly Zinc based Micro-Layer Corrosion protection coating Technology for mass produced Hardware & metal parts according to ISO 10683.

Zinc Al Flake coating offers high performance corrosion protection for metal components

The layer is made up of Base coat and top coat

SST 500-1000hrs. As per customer's requirenments

COF control from 0.08 to 0.20

Chrome free Coating

Coating Compliance with ROHS, EVL, REACH, WEEE

The layer is made up of Base coat and top coat

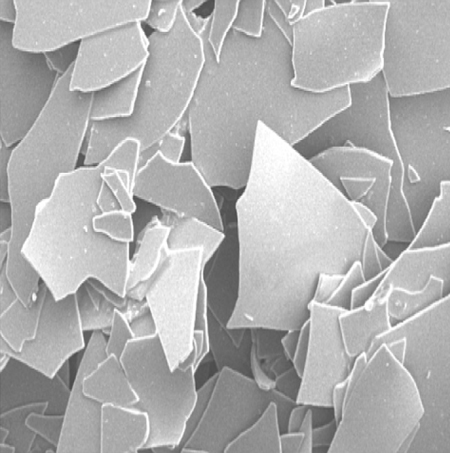

Zinc Al Flake coatings were made by combination of Zinc and Aluminum flakes, electrically conductive Binder system with integrated lubricants for adjusting co-efficient of friction. The coating is conductive which helps to protect catholically and aluminum flake helps to reduce of white oxidation build-up. The Zinc Flake coatings are Non-Electrolytically applied (as per IS010683/ASTM F1136) by mechanical application techniques with combination of Organic or Inorganic top coat sealers. The coating could be an alternate to zinc and other electroplating in terms of properties and pollution related aspects.

Zinc Al Flake coating offers high performance corrosion protection for bulky metal components. It is applied using a so-called dip-spinning process. The layer is made sofa base coat and top coat. The base coat is made up of zinc and aluminum flakes; the zinc gives cathode corrosion protection. What is more the zinc and aluminum flakes produced in the dry film form a barrier to reduce the impact of corrosive media including oxygen, electrolytes, etc. thereby enhancing the life of the complete protective system.

Zinc - Aluminium Flake Coating Properties

SST 500 - 1500 hrs as per customer's requirementBright Silver and Black Finishes

Freedom from hydrogen embrittlement

Coating process environmental friendly, no release of hazardous gases, liquid or solid

Suitability for multiple torqueing

COF control from 0.08 to 0.20

Chrome free Coating

Coating Compliance with ROHS, EVL, REACH, WEEE

Barrier as well as cathodic protection

Coating Suitability for high temp. Application up to 350C

Coating process environmental freindly, no release of hazardous gases, liquid, or solid.

Good UV resistance/abrasion resist

Suitable for applications in Marine, Industrial, Humid, Costal environments